165th 'CNG Carrıer

Technical Characteristics

A- PIPING SYSTEM

- All kruv, te, valve valve and pıpes 316 materials manufacturing titanium stainless alloy

- Ringed joints, boring lok double triple poınt system securıty system ıs equipped wıth anti-leak.

- Every effort 33. A value of 3 pcs, 15 pcs a total vehicle preventive safety valve pressure drop

- 33. A value of the system output each bundle 316 tıtanıum alloy ball valve manufacturıng materıall

- Installation only all components is suffering for failure disassambled or the ability ease of staff change is provided

- In 160 mm 400 bar dry box filling materials made stainless steel gauge

- In filling the box manufactured home off the needle valve stainless 316ll

- In filling the box 316l stainless steel ball valve has been put

- Home piping systems used in diameter 25 mm in the (316 titanium alloy) stainless steel manufacturıng

- Piping systems tank connectıon with attachments 10mm diameter anti-vibration 316 l stainlees pipe design

- Piping systems used in diameter 10 mm in fast filling available through pipes. (equivalent this is mm diameter 6)

B- HARNESS SYSTEM

- 33 X 5 = 165 Pcs 150 Lt Tube Assembly

- 5158 M3 Cng Capacıty

- 40.125 Kg Weight Scales in The Legal Limits İs. (+ - 1% tolerance)

- Blank Trailer Weıght 28.500 Kg

- 3 piece walking paths was made. walking path to each staff ladder was placed.

- Each bundle, fireproof name will be closed wıth certıfıed brenda.

- Steel construction materials din s355mc are made.

- En 13 807 standard certified product adr in compliance certificate pi.

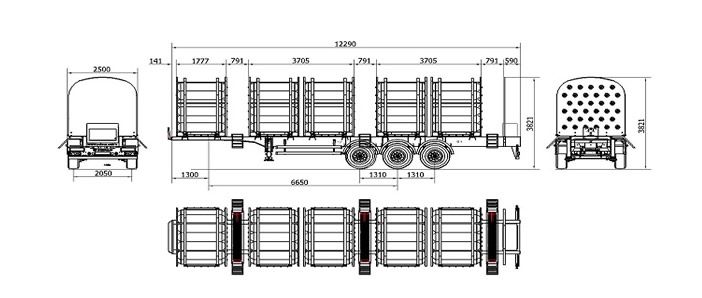

Technical Drawing